Chaircito is a chair. The suffix "-cito" is Spanish for the diminutive. It means it's smaller. This is a small chair.

It is cozy and gives the sitter a small defensible space. The high sides allow for easy resting. Sitting in the chair feels like sitting in a nest.

What makes this chair unique is its plywood core. Traditionally, a chair like this would be made from a polyester (or other plastic) injection-molded core.

A plastic core of similar rigidity would be several times the cost of this plywood core. It is upholstered in "Plaidtastic" by Knoll. The legs are black walnut.

Oregon is the largest lumber producer in the US.

However, the majority of this lumber is used for building construction. The Oregon climate engenders fast-growing coniferous forests, such as pine and fir. These softwoods are usually deemed lesser for woodworking.

The Problem

So much wood and so little chairs! The local economy is geared towards the building materials market. There is a wealth of expertise in plywood.

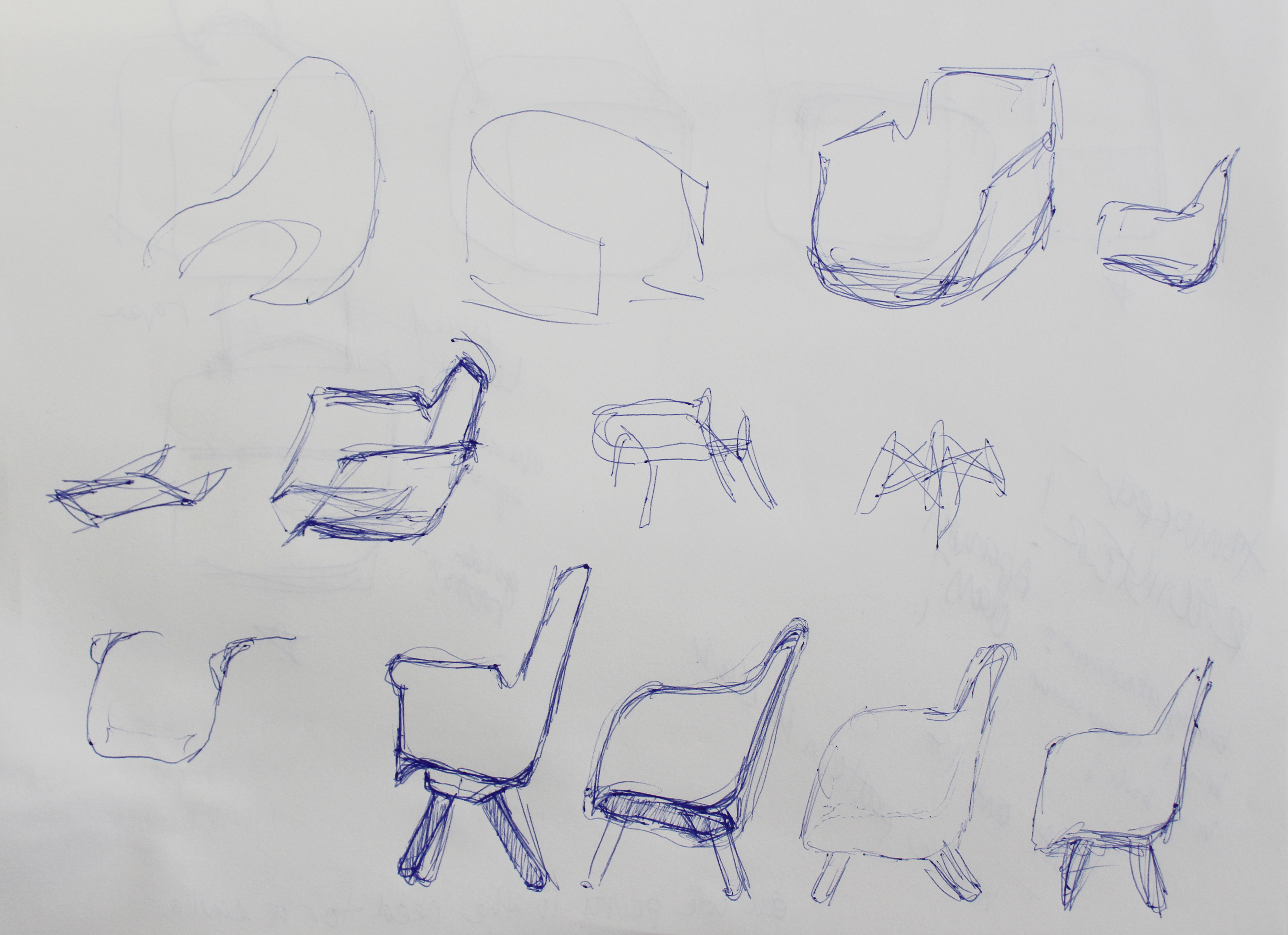

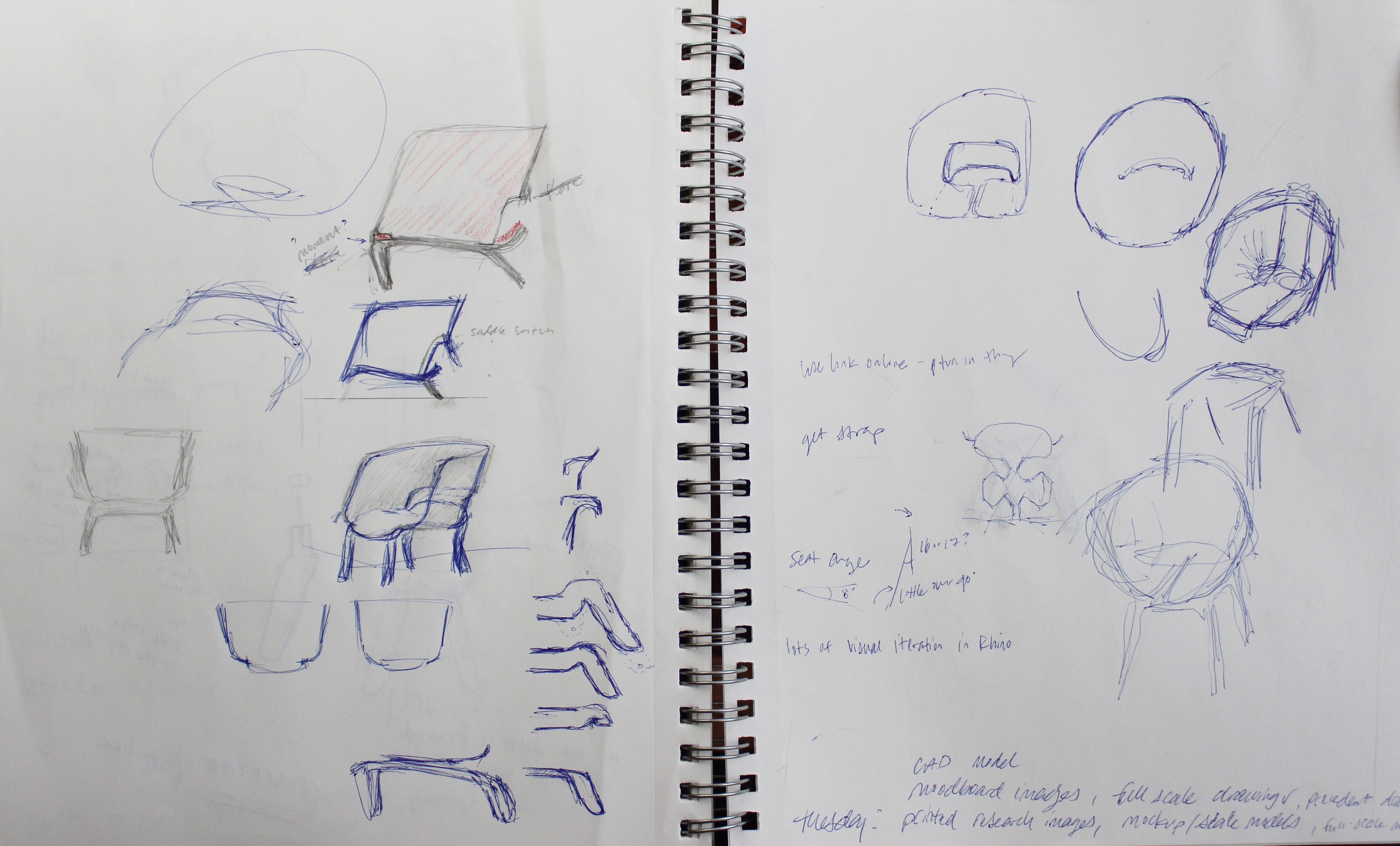

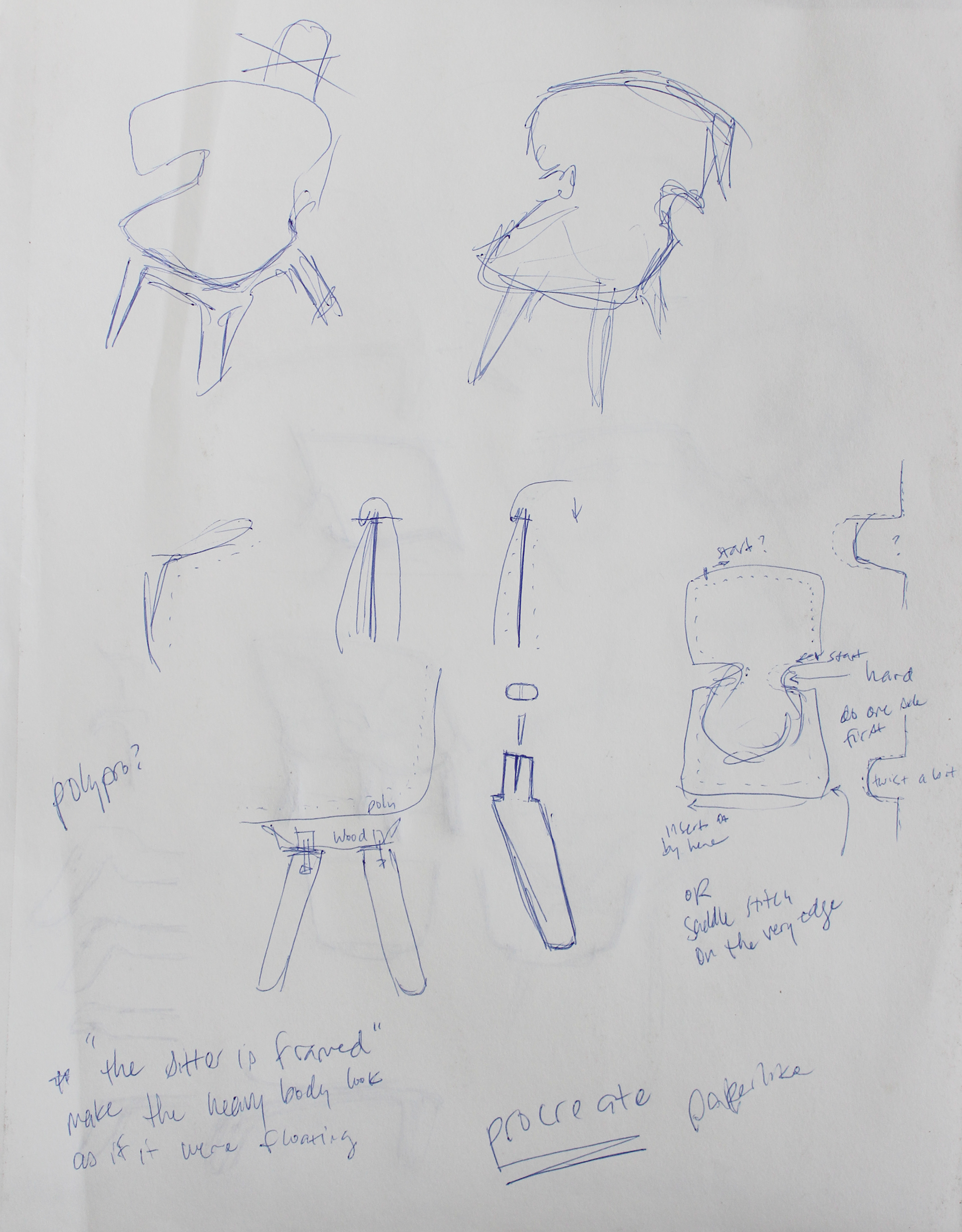

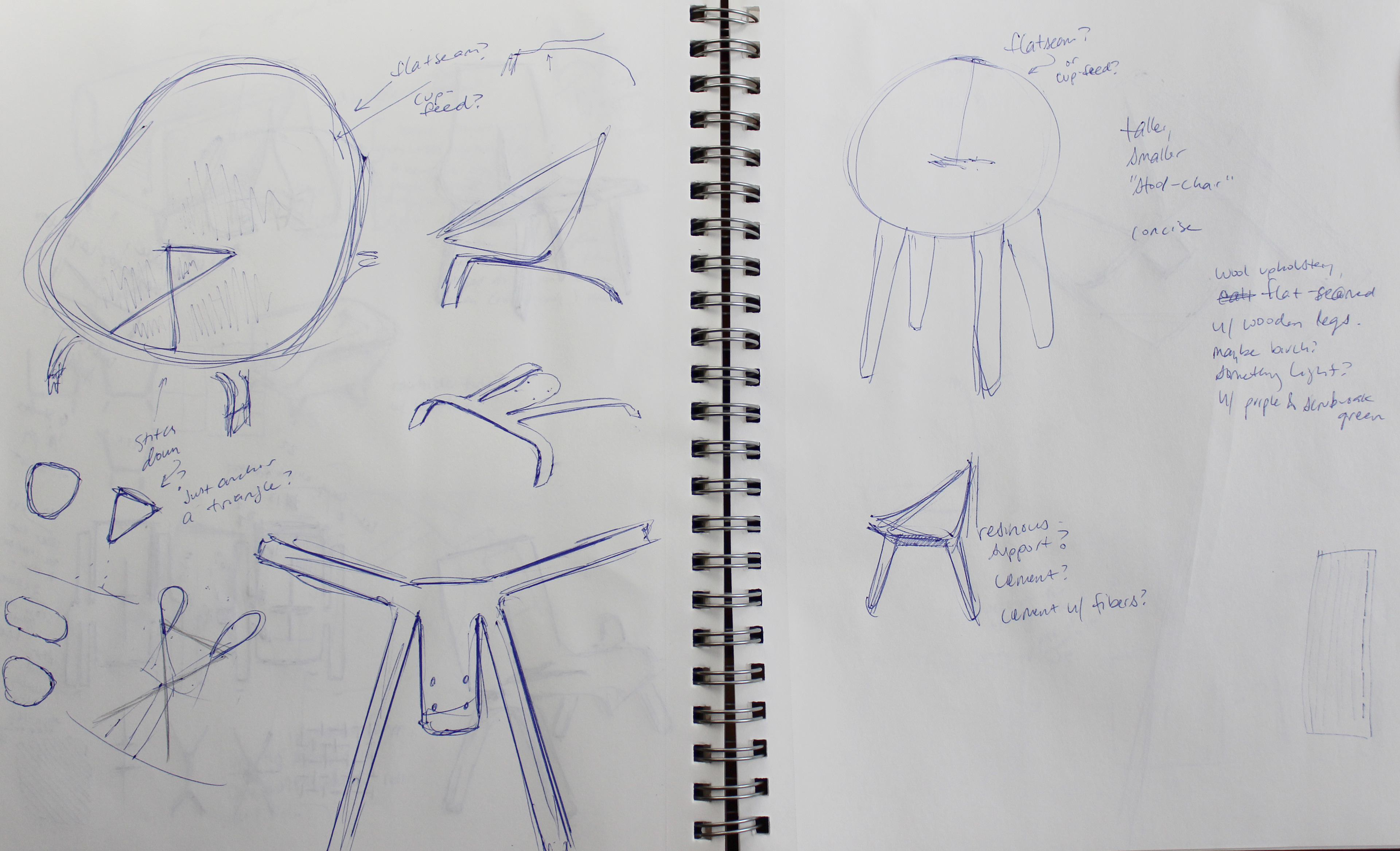

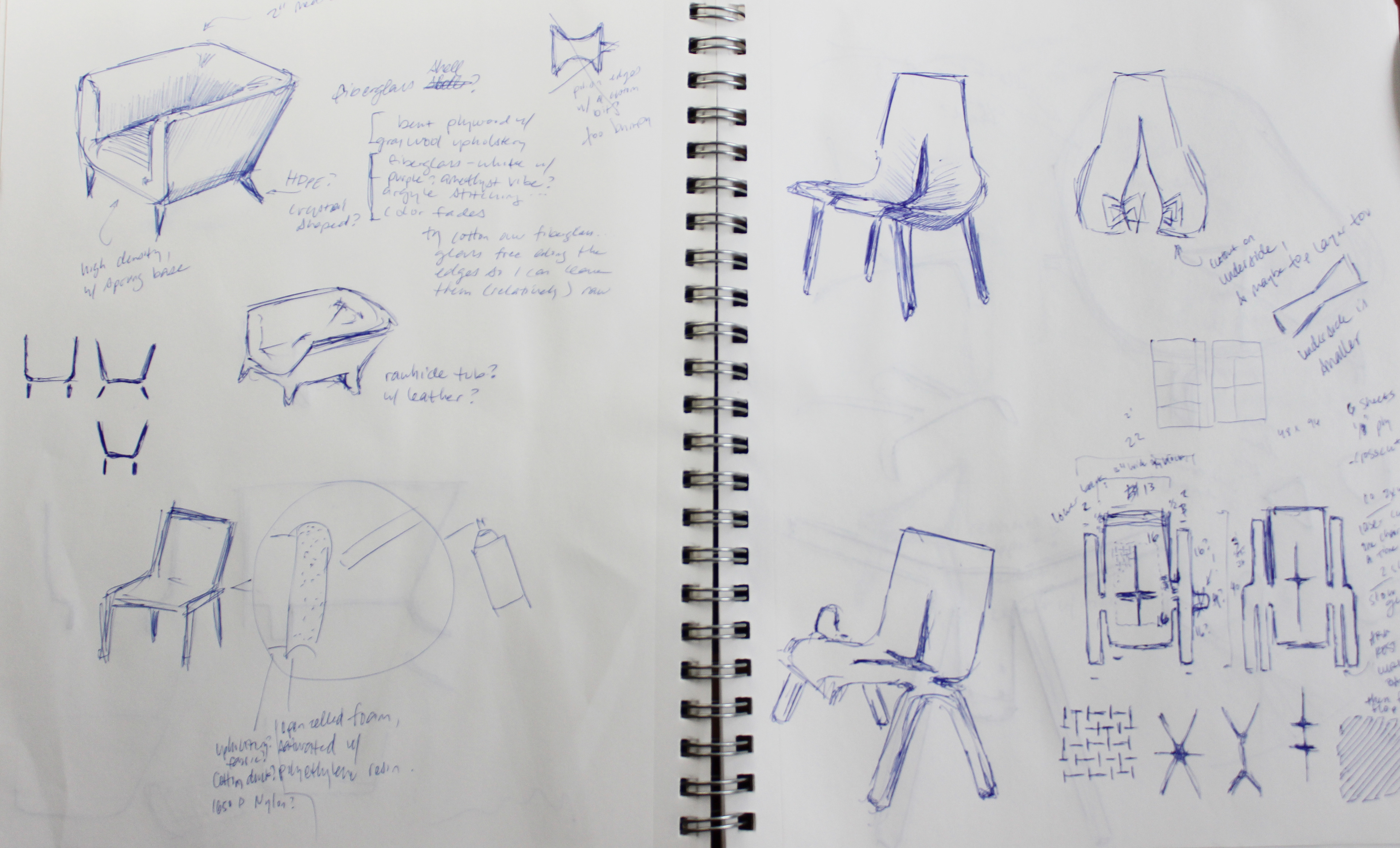

To make this chair functional, all measurements were considered important, down to the radii of curves on the edges. As mankind has been sitting for millennia, a lot of work has been done before me. I found the work by Humanscale to be useful. I also found measuring (and sitting on) every chair in sight to be useful.

I went down many unfruitful paths testing the properties of bent ply. I feel that innovation at the material level will be the key to opening up design possibilities in a field where so much has been tried. An intimate working knowledge of plywood seems key to moving forward.

While I got a little done here, I feel I'm far from even knowing what I don't know on the subject.

The Other Problem

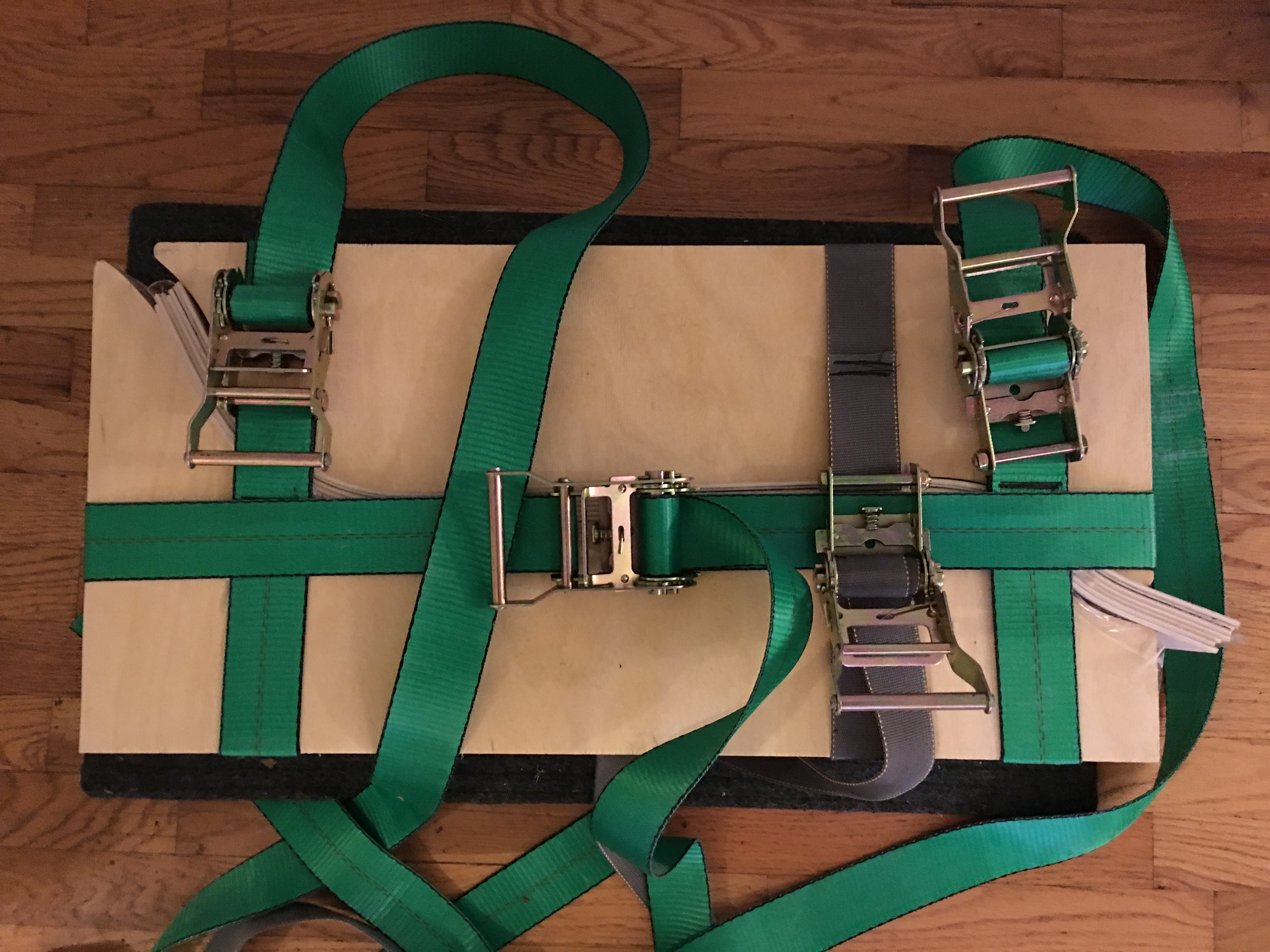

With that in mind, I pressed on with the iterative development. Turns out, plywood can be thought of as a two-dimensional plane. It only wants to bend on one axis at a time. Complex curves have been considered basically impossible. Actually, they've been considered literally impossible.

This made me want to do that. After many tries, I do believe mankind presently has the technology and means to make a chair with complex plywood curves. Presently, that technology is a lot of time and money away. But I tried!

As a workaround to the present unyielding nature of plywood, the outside of the chair is upholstered, as well as the inside sitting area. Using three different types of foam, the chair came together well.

Reflections:

The small size is endearing. It is cozy to sit in and scroll. The high sides raise the elbows up enough to prop up your head on your fist.

In the future, it could be about 4" taller and 6" wider. It could lean back a little more, the seat depth could be shallower as well.